What’s new is old again.

Sometimes, an idea seems so great that you just can’t let it go, even though you should. Today’s hack is one of those, and it’s not headed where you think it’s headed.

Previously, I got the IIc Plus up and running, and booting software. However, I’m not actually able to use it for anything because my stopgap display solution is too low fidelity. Besides, the IIc deserves better than some crappy digitizer pumped into a tiny window on some other screen. These machines had big, bright color displays which were amazing to look at. The world was not yet full of HD LCDs everywhere you look, so a big computer-controlled color display was something to see.

There are a couple of options here. The first is to simply buy a monitor with a composite input. There are some still available. However, they are generally 16:9 aspect ratio. It’s getting very tough to find 4:3 aspect screens anymore. Sure, some widescreens can pillarbox the content to show 4:3 in the center, but that always sort bugs me. I also want something that suits the machine visually. There are lots of cheap plastic junk monitors for sale online, but I don’t want any of them sitting next to my IIc.

The second option is to hack something. I know I don’t have to go any further- you already know what I’m going to do.

First things first, I need a screen. It needs to be around 10″ in size, decent resolution, color, 4:3 aspect, and of course, cheap.

Yep, the junk pile coughed up an original iPad that has been gathering dust since 2010 or so. The sad fact is, it works perfectly fine hardware-wise. However, it is no longer supported by iOS, so there’s virtually no useful software that it can run. Sure, I could jailbreak it and do some stuff, but I have a better idea. It’s thin, light, color, and 4:3 aspect. Let’s make an Apple IIc monitor out of it. Aside from the joy of upcycling this thing rather than wasting it, there’s something cosmically satisfying about using a forced-obsolete Apple product to breathe new life into a classic-and-still-useful Apple product.

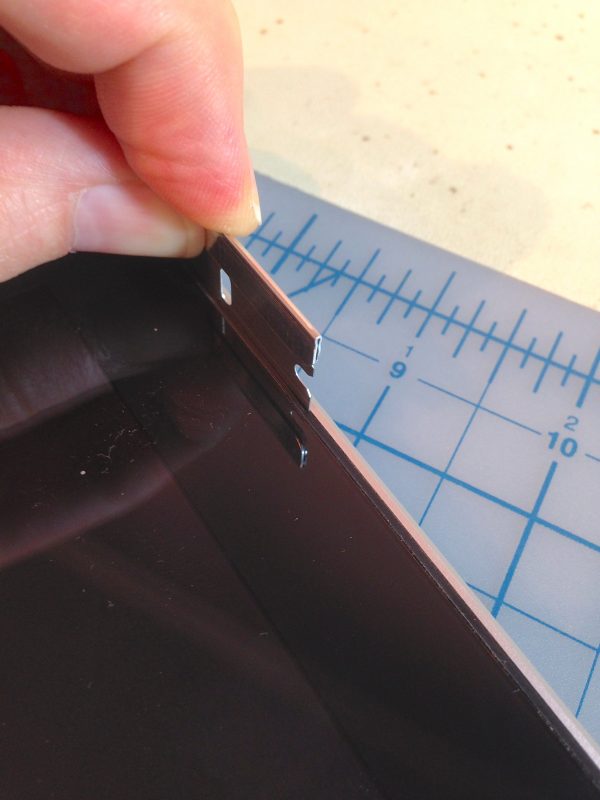

We need to separate the iPad screen from the guts. There’s something called a “metal spudger” that you’re supposed to use for this. However, if you don’t care about the iPad surviving the process, a razor blade and small screwdriver work fine. All that is needed is to pry the edges of the screen up all the way around. A bunch of internal mounting clips will get broken since we’re not using the right tool for this, but “meh”.

Here we have the guts all laid out. The screen assembly on the right includes the display, backlight, capacitive touch panel, bezel, and the Home button. On the left is the logic board, batteries, and casing. You can also see all the shit that broke taking it apart. See earlier, re: “meh”. Once inside, everything is held together with T4 Torx screws.

Let’s take a quick sidebar to dismantle the other half as well. Why? If you have ask why I would take something apart that doesn’t need taking apart, you’re reading the wrong blog.

Visible there is the speaker assembly (they look like little fans), a main harness that connects the Dock port and Wi-Fi antenna to the motherboard, the motherboard, various switches and sensors, and a power harness. Still mounted in the case are the Li-Ion batteries. They were covered in a layer of black tape which I’ve removed. The batteries themselves are held by a plastic frame bonded to the case, but are otherwise removable. Well, sort of- the tabs are spot-welded to a harness which may or may not be removable. I’m opting to leave it be for now.

What I hope to demonstrate here is that modern electronics are absolutely hackable. They can seem very intimidating because of the lack of visible fasteners, and high level of miniaturization. However, anything that is assembled can be disassembled, if you have the right tools. In the case of Apple products, a set of spudgers is usually all you need. At worst, sometimes a heat gun is required to release adhesives. If the product in question doesn’t need to survive disassembly, things get a lot easier.

As you can see in the above photo, modern or classic, electronics haven’t changed as much you might think. It’s still assemblies joined by harnesses, mounted in an enclosure. Things have gotten smaller and the connectors are more exotic, but that’s why we have head-mounted magnifiers.

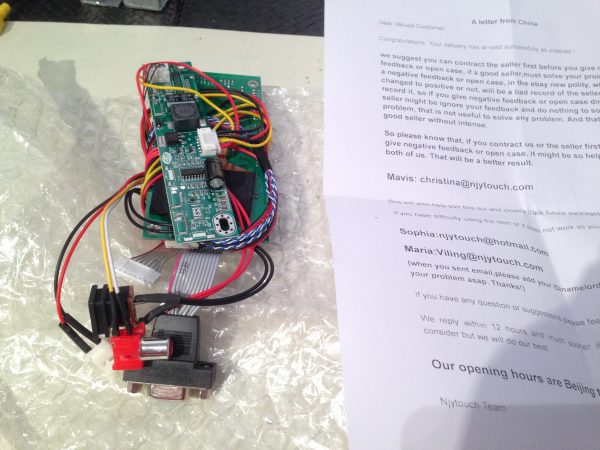

Okay, we’ve murdered an iPad for science, now what? Those screens sure as smurf aren’t usable on their own. In fact, the iPad screen is, like most consumer devices these days, interfaced with a high-speed Low Voltage Differential Signal serial protocol. This is not very easy for us to talk to, especially when what we have is a composite video signal. What’s needed is a driver board. Luckily, thanks to globalization, driver boards for every LVDS panel under the sun can be bought directly from China. If you have an LCD you want to reuse, you can. It’s just a matter of finding the right driver board. That can be easier said than done, but AliExpress or eBay will have what you need.

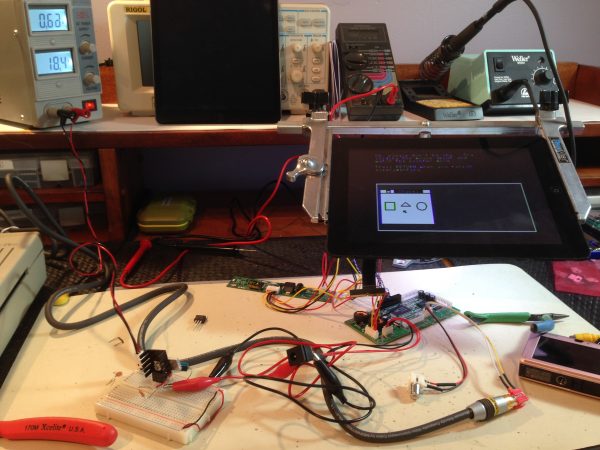

So, bully for us, we’re all set, right? Let’s hook it up and see what happens. It needs 12V, and the package came with boards to drive both the display and the backlight (but not the touch layer).

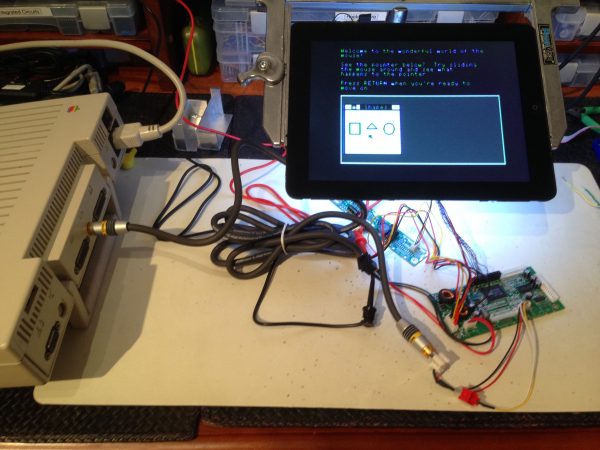

Now for the IIc Plus…

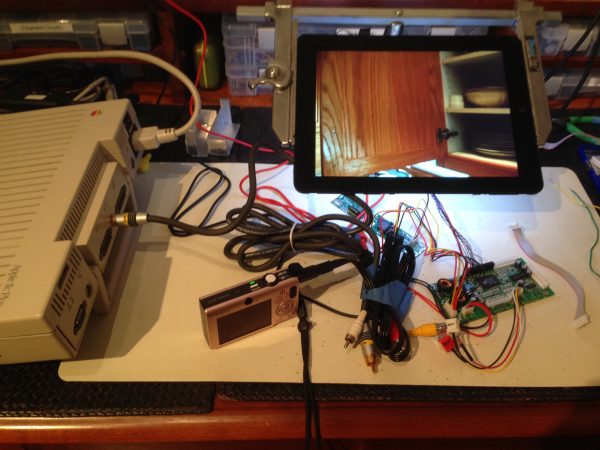

It wasn’t clear if the driver board has a crappy composite decoder, or if it doesn’t like the not-quite-NTSC output of the IIc. I tried another composite source, my digital camera.

Not yet deterred, I thought maybe it’s being fussy about the power supply. I don’t know how noise-free my bench supply is, and I learned on Veronica that display circuitry can be particularly fussy about power quality.

This was the hardest part of this hack- knowing when to fold ’em. I really really love the idea of turning an iPad into a display for my IIc, but this driver board just seems to be garbage. It might be useful for some other purpose where quality is less critical, but for my IIc’s main display it isn’t going to cut it. There are other similar driver boards on AliExpress, but this is the only one I could find specifically designed to drive the iPad display. Furthermore, it took many weeks to get it shipped here, and I was in no mood to wait many more weeks just to spend more money and try another board that might not work.

For Plan B, I thought I’d take apart an existing LCD display that I have. I’ve been using it for Veronica, and it doesn’t have a composite input. However, just because a monitor doesn’t have a composite input, doesn’t mean the driver board inside can’t support one. Oftentimes manufacturers continue using old boards inside products with obsolete features on them, but they remove the connectors and external support points to save cost. If users no longer want a feature, it’s cheaper to continue making the same board, but simply remove external access to the feature.

Okay, Plan C. I’m going to acquire a monitor with a composite input and modify it for my needs. However, I have some unique requirements that are difficult to fulfill without spending a ton of money:

- It must be in the 8-10″ size range

- It must be 4:3 aspect ratio

- It must have a composite input

- It must cost less than 100USD

If you just search usual sellers of electronics, such as Amazon or New Egg, you’ll click around until you’re blue in the face and never find something that meets those requirements (ask me how I know). The key to sourcing a part for a project is often understanding the kinds of markets that use the types of parts you need.

In this case, the usual markets for LCDs, such as TVs and computer monitors, have long since gone to 16:9 aspect ratio, and are always much larger than I need. With a little research, I found the following market segments still use smaller-size 4:3 LCDs with composite inputs:

- In-dash car displays (but not headrest displays). These are great in theory, but because they are aimed at notoriously deep-pocketed car-stereo people, they are very expensive for what you get. The overpricing in this market segment is fairly astonishing.

- Point of Sale terminals. These are reasonably priced, however nowadays they generally come bonded with a resistive touch panel on top. This is both unnecessary for us, and adds a lot to the cost.

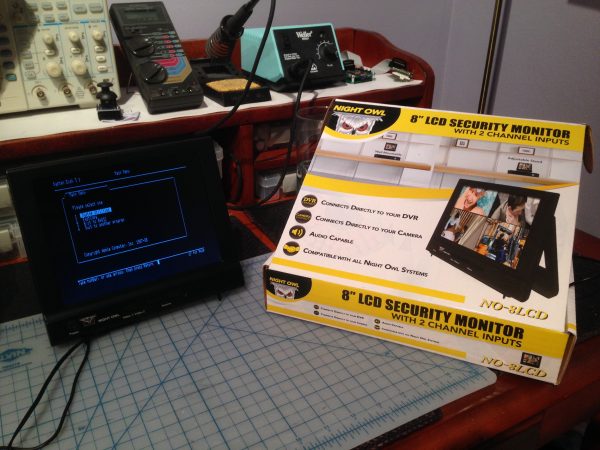

- Security systems. Here’s where I hit pay dirt. Closed-circuit and security video systems are still often 4:3, and generally composite signal-based. Once I knew this was the market segment to search in, the google results became fruitful.

The answer came in the form of the Night Owl 8″ LCD security monitor. It’s 4:3, has composite inputs, and cost less than 80USD (as of this writing). This is what the doctor (Quinn, Medicine Woman) ordered. I took a chance that it would render the IIc’s output nicely, and my gamble paid off.

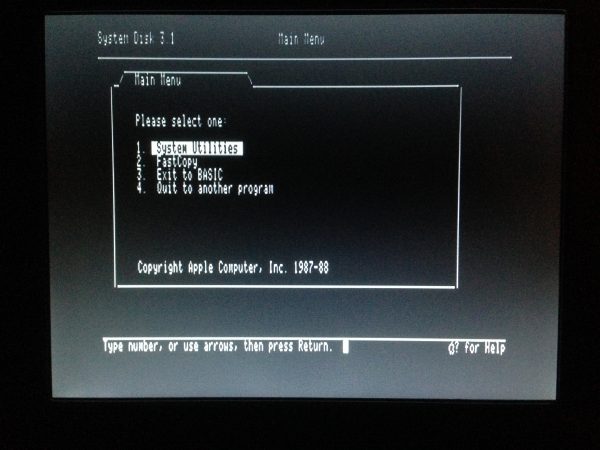

The picture quality is great, even on the notoriously-difficult 80-column text display. It’s hard to find something that renders this text mode properly, but this little budget security monitor does so without breaking a sweat.

Of course, I’m far from done with this display. As I stated at the top of the article, I don’t want some plastic junk display sitting next to my IIc. This security monitor currently fits that description, but not for long. I have big plans for it, so stay tuned. In the meantime however, I can finally get my Choplifter on.

Thanks for the post. I enjoyed it.

How do you go about figuring out which market segments use the types of parts you need? If it were me, I would have hit the wall when the Chinese decoder board didn’t work. I am not sure how you start researching marketing segments. That seems like a useful skill to have; any chance you can shed some light on your process for that?

Thanks.

That’s a great question. Basically, it’s a research process, much like trying to figure out any other sort of engineering problem. I started by googling the general concept I was interested in. I probably started with something like “composite 4:3 LCD”. From there, you start to see the kinds of sites that return hits and can drill down. I filtered out all the results involved TVs or computer monitors, since I knew those areas wouldn’t have what I needed. Looking for patterns in what was left, I started to notice things like car stereos, security systems, and cash registers getting mentioned a lot. From those sites, you pick up the jargon used in those segments. Knowing the jargon is key to fruitful googling. Googling for “point of sale terminals” gets you much better results than “cash registers” for example. Similarly, in the car stereo area, I learned to search for “in-dash displays”, while excluding “head units” and “headrest monitors”. Once you have a few types of products that might solve the problem, then you can google that on Amazon, AliExpress, or other retailers. That’s how I landed on the security monitor at Amazon.

Thanks! That’s really helpful.

It’s interesting to see your progress getting your Apple //c+ up and running. I had a //c as my first computer and it was a lot of fun. I recently picked up an Apple //gs, a machine I never really had at home or fully utilized. I’d like to get it running with a nice display, but true CRT RGB’s for these things are super hard to come by. I’ve been thinking of making a scan doubler for it using an FPGA to convert it to VGA or DVI. For the IIgs people have also used the gbs-8220 which is a scan doubler popular for arcade boards, but I don’t think that supports composite.

It seems like getting good video of any Apple II is tricky, because of the quadrature color trickery that Woz did. People even say that the Apple IIgs playing DHGR games looked worse, because the Apple IIgs did only a “passable” conversion to RGB.

Yah, IIgs video is tough. It’s an unusual format that wasn’t well supported back then and is tricky to convert today. I have a GS in storage as well- it was my favorite machine, probably of all time. It’s well worth the effort to get the video sorted out. If you can’t get an original GS monitor, Nishida Radio makes a component video adapter which is reportedly very good.

http://tulip-house.ddo.jp/DIGITAL/ANALOG_RGB_COMPONENT/english.html

I went a different way with my IIgs. For about the same as the under $100 limit you placed on the IIc PLus monitor, I found a site in Europe with inexpensive (but well built) IIgs video to SCART cables. I use that with an inexpensive SCART to HDMI converter and have it plugged into my 26″ LCD monitor. The video output is quite good and because it uses the SCART cable to connect to the IIgs, it also includes the audio signal and the HDMI passes the audio on to my monitor as well. It works pretty well and I can pass through a HDMI signal with the converter as well, so I don’t even have to unhook my computer or satellite receiver’s HDMI connection. It’s more of a duct tape-type solution than a hack, but I’m very happy with the results.

That sounds like a cool solution. Is there any delay in that? Some of these conversion strategies introduce 50 or 60ms delays in the signal, which really messes with action games. I also wonder about FTA demos with border effects? I don’t think I could live without those. 🙂

Likely not useful for this particular project, but it might be worth investigating any S-Video inputs on the iPad display adapter board.

I’ve got a cheapy composite/s-video to VGA upscaler box I bought a few years ago (I was messing around with an old PS2 and didn’t have a suitable display) – the picture quality for composite input is absolutely dismal, akin to a multi-generation VHS copy, but its S-video is really quite good.

Interesting idea! Sadly, no such luck on this board. It has two composite inputs (for some reason) and a VGA input. The board is basically a single chip with some support passives, so I suspect this is an off-the-shelf IC intended for backup cameras or security systems. Those seem to be the two areas that want multiple composite inputs on a single panel. It even boasts automatic switching to whichever composite source was most recently activated, further reinforcing this theory.

I wonder if you could do a similar build with the LCD from a 12” G4 Powerbook. I have a couple of those around.

Can you share some of your method for finding the LVDS driver boards? Should I start with the LCD part # and troll alibaba?

Hey there, stranger. 😉

Yah, I bet you could. The challenge for newer displays is sometimes power source. As you can see in some of those photos, the backlight on the iPad draws almost an amp(!). Some of these driver boards come with a power supply for the backlight, but some don’t. Depending on the screen, those power requirements may be fairly high, and may require a dedicated power supply.

As for how to find the right driver board on Ali/eBay, I won’t lie- it’s not easy. There are a LOT of them, and the pictures and descriptions aren’t always helpful. Keywords are dangerous as well. For example, they virtually all have the word “composite” tagged on them, even when they don’t have a composite input. This is probably some combination of lazy cut-and-paste ads, and sellers wanting to show up in as many search results as possible. Same for photos- they are often not of the product itself, and should be greeted with suspicion.

The driver boards are specific to native panel resolution, so that’s a good place to start. Some vendors, like njytouch, have a storefront on eBay that is organized by panel resolution. Searching on terms like “1024×768” or just “1024” seems to help. Searching on LCD part numbers does not seem to work. The Chinese seem to use different part numbers for everything. I’ve often found panels for sale with part numbers that don’t turn up anything in Google, but later I find out they’re a standard Samsung panel or whatever.

I would also recommend starting the search on eBay. Their search tools are better, and many Ali sellers sell there as well. Once you have a Chinese part number or product name that you know is the thing you want, you can try searching AliExpress to possibly get a better price. Don’t bother with AliBaba- the minimum orders will all be too high.

AliExpress’s search tools are really awful, but when you think you’ve found the thing you need, send a note to the seller with questions. Their English is probably very poor, but they are genuinely interested in customer service. My iPad driver board arrived with a part missing, and they were very apologetic and helpful at getting it replaced for me. However, it took about ten emails and some photos to work through the language barrier and establish what they needed to send me. 🙂

Oh, and then be patient. The parts can take weeks or even months to arrive. My iPad board was close to three months, IIRC.

And according to the tracking, it shipped right away. There were delays due to various Chinese holidays and government red tape, and depending on whether the container it’s in winds up on a Panamax ship or one of the bigger ones, it will vary a lot. The trip around the horn takes a hell of a lot longer than the canal.

It’s somewhat funny. I mean the iPad being obsolete, and nothing runs on it anymore while the main character of the post (the Apple computer) is even much more old, and still it wanted to be saved 🙂 No problem with this of course (I would save the Apple IIc as well !!), just it’s funny to think about it, how fast nowdays something to be obsoleted and not used by anyone anymore, while having much older computers still used by some people who don’t want to “upgrade” of course 🙂