Rescuing yet another almost-great product.

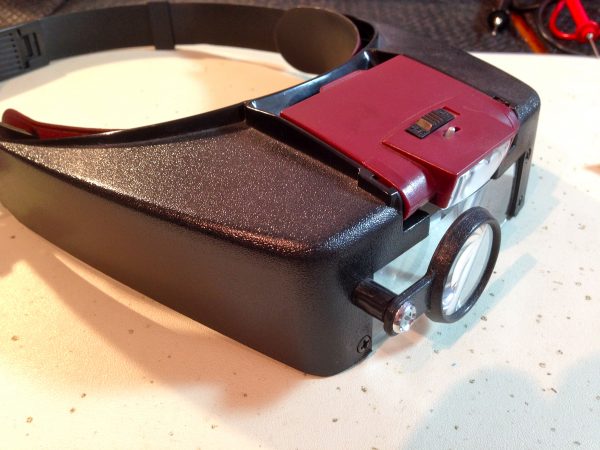

One of the running themes here at Blondihacks is rescuing products from the landfill when they “barely fail”. That is to say, one single element of the product was under-engineered, greatly shortening the lifetime of the overall system. In this case, it’s a head-mounted magnifier. You know the one, because some factory in Asia is cranking these things out at a furious rate. They are sold in a hundred places under a dozen different brands, for a lot of different prices, but they’re all identical.

I bought mine on eBay, from a storefront that appears to be one of those direct portals for a Chinese factory that we all know and love. These seem to be commonly used to unload surplus, or to market the output of an off-the-books third shift. It was listed at Buy It Now for $11 (USD), but had a Make Offer button. So I offered $5. The vendor came back with $8, so I pulled the trigger. Eight Freaking Dollars. Shipped. From China. At that price, if it only works twice, I probably got my money out of it. There are rather a surprising amount of features, as well. Two primary magnifying lenses, which can be combined in different ways for different magnifications, a bright LED light that tilts and swivels, a front mounted loupe that can be swiveled in or out, and an adjustable headband.

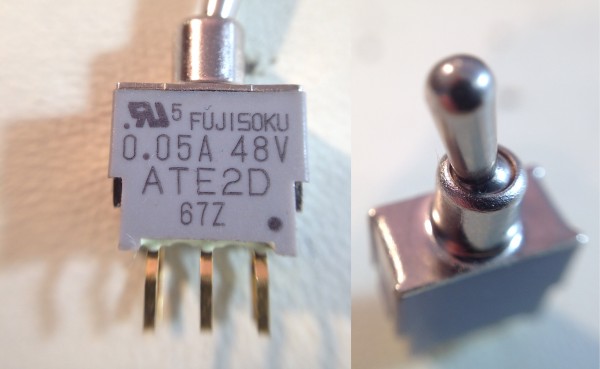

With a list of features like that at such an impossible-to-believe price point, you know corners are being cut. In my experience, the corners are usually cut on mechanical elements. Fasteners, switches, hinges, connectors, that sort of thing. Electronics and plastics are cheap in any product. It’s the mechanical elements that are expensive. Have you shopped for quality toggle switches lately? A good one (rated for many thousands of cycles) costs more than this entire headset.

So what failed here? Well, after a few months of regular use (mostly while building Veronica), the LED light started flickering. The batteries were fine, but the light wouldn’t stay on. I gave up on it and continued to use the magnifier without the light. This works okay, but I really missed the light. Having white, focused light shining on exactly what you’re looking at is really nice. I wanted that back. Also keep in mind that any magnifying lens requires extra light. As any photographer can tell you, lenses eat light, and cheap plastic ones like this, even more so.

I could buy another one (for eight freaking dollars shipped), but that’s not the Blondihacks way. I had to crack it open and see what the problem was.

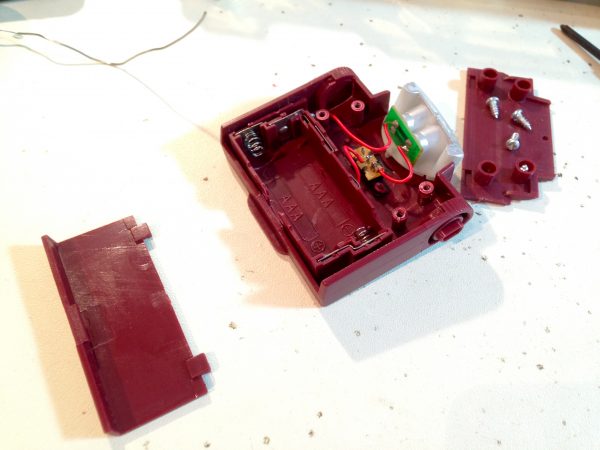

Inside, you can really see where the corners were cut to hit that price point. The switch is plug-melted in place and all the solder joints are cold. The latter were clearly done by hand, probably at a piece-work rate, so the worker was motivated to do it quickly. One of the contacts on the switch has been overheated from the soldering, as well. It’s badly burnt.

After testing the batteries to make sure, I checked the LEDs themselves by applying power from the bench supply. No flickering. That left only the switch. I checked it for continuity, and immediately got intermittent beeps. In a turn of events that surprises nobody, the world’s cheapest switch has failed.

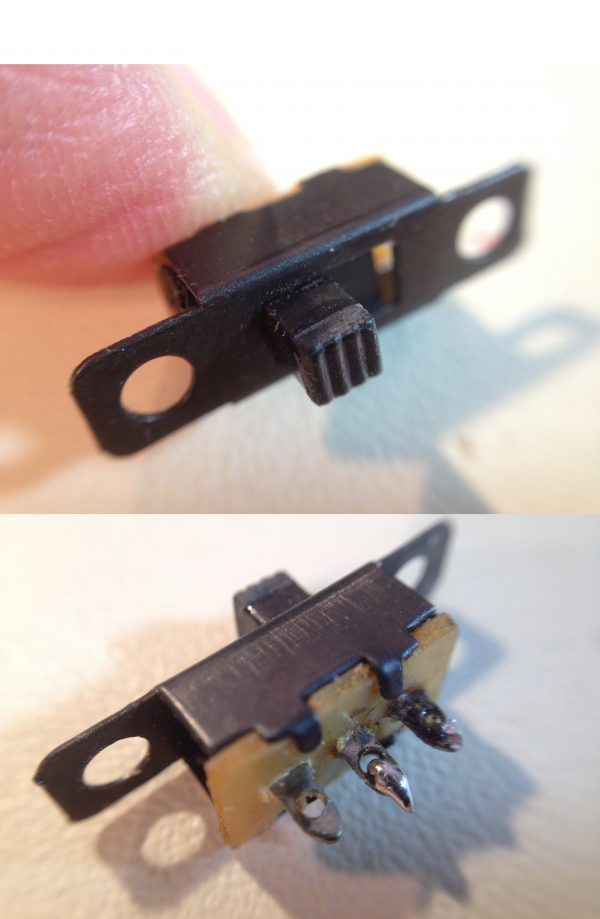

Seriously- this thing is made of hopes and dreams. It’s the flimsiest little switch I have ever seen. Even at this small size, you can tell how cheap it is. It’s probably rated for 20 cycles. It doesn’t even have any part numbers, specs, or markings of any kind on it.

Luckily, that’s an easy fix for us. To the junk pile!

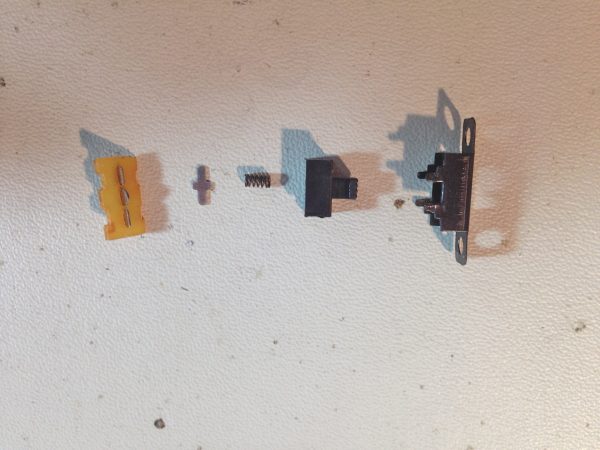

Not being able to leave well enough alone, I wanted to know what was in that slider switch and why it failed. Nothing for it but to crack it open.

The cross-shaped metal piece is perched on the pointed center blade, held in place by the plastic slider knob, and the spring. When the switch slides, the spring causes one side of the cross to rock over to that side, closing the contact. This all only works if everything stays tight and perfectly aligned. Alignment is only maintained by the metal pieces being pressed into a scrap of phenolic. Tension is only maintained by the folded metal tabs on the outer casing. The metal cross appears to be held in position over the contacts by rainbows and whale songs. There are about 14 points of imminent failure in this switch. Time to deep-six it.

A new switch, a little superglue to hold it, and we’re in business. For good measure, I re-did all the terrible solder joints that were in this thing. Every one of them looked like it could have been the next failure point (if not the current one!).

There’s an interesting math you can do in the modern globalized world. Sure, it’s easy to say we should always get the better quality product, and this “race to the bottom” in consumer products is bad for the planet. But sometimes a product this cheap is actually almost quite good. It was clearly very efficient in both labor and materials to make (otherwise it couldn’t be this cheap), and if we keep it out of the landfill, it’s actually a net win all around. I’ve gotten a couple of years out of this thing so far, and I should get many more out of it now, all for far less strain on the environment than a higher quality headset would incur. So, the moral is, environmental stewardship is really about efficiency, and what’s genuinely efficient isn’t always obvious when you consider the whole lifecycle of a product, from materials and manufacturing on up.

Okay, okay, I’ll get off my soapbox. I’ve got things to do with my “new” headset!

Great fix, Quinn! And nice points about efficiency.

You could have mentioned that cheaply made items break, and broken items provide learning / teaching moments. It’s how we react that makes the difference.

Don’t get mad, fit it!

Great fix! Ha! I’ve got the same model sitting on my desk right beside me. My only problems with it is the small round lens on the front, the screws on the sides and the headband adjustment all seem to come loose. Not that big of deal at the moment, but I may eventually come up with my own fix for this one of these days.

Really enjoy your blog and especially the snarky take on electronics.(it matches my own.)

If snark was a competitive sport, I’d be nationally ranked. 🙂

Agree with you on good design — and on ‘hacking’ repairs together. You should hear what I wound up putting together recently when replacing a couple caps on a Dell board went slightly wrong… oh, and Dell uses high temp solder, BTW — ugh!

Oh, what the —-. What happened was that one cap left its legs in the board and my iron didn’t have the oomph to fix it. I wound up scrapping together a drill (since I don’t have a chuck for my dremel yet) out of a spare switch (the 25amp “flip switch” from Radio Shack!), some random speaker wire, four C batteries, and the last remnants (motor, gearbox, and chuck) of a Craftsman rechargeable drill that my mother had purchased in the Mid-Nineties. (You know the one… all black, plastic housing of course, with six volts of NiCD inside, and a very-probably-unregulated wall wart for charging. Batteries weren’t Y2K compliant or something, because that’s about when they popped. I took the drill apart a year or so ago to see why it died, and the only stuff salvageable was what I saved.) Used a 1/32″ bit in the chuck because that’s the smallest that would fit. Mounted the battery holders (each taking two C batts) and the switch in a spare food container with foam tape.

My new scrappy PCB drill isn’t very enthusiastic (I think I need to upgrade it to D batteries… but I don’t have a 4D holder…) but it did the job… and it made me laugh. Didn’t have to buy a thing, and it’s uglier than sin, but it does what it needs to do…

By the way… I don’t see a mention in your article… the little lamp *does* have at least a single resistor for current limiting, riiiight? (Good lord I hope so! Got a dollar store flashlight once that didn’t… it burnt itself up in two days flat. Intermittent usage, of course…)

Haha, well done. I’m imagining a ball of parts taped together that somehow approximates “drill”. It should serve you well in the zombie apocalypse.

I can definitely recommend the Dremel chuck. One of the best things I’ve ever bought for it. I grudgingly also recommend the Dremel drill press if you do a lot of PCB drilling. I say ‘grudgingly’ because I swore for years I would never buy a frivolous attachment like that. I finally caved though, and it’s actually really nice. Takes the tedium and sore hands out of drilling homemade PCBs. Much easier on drill bits, too (no sideways flexing).

Put the drill up for a photo op, here –> http://i.imgur.com/R14DtIz.jpg

Warning: large image (well, large*ish* — it’s straight from my 7MP camera…).

Enjoy 😀

Haha, well done. Thanks for sharing.

Oh- I forgot to answer your question about the current limiting resistor. As you say, it must have one, but it isn’t apparent. The LEDs are of the sort used in lighting fixtures, so they must have an internal current limiting resistance. Like you, I was curious about that, but there’s no external resistor. They wouldn’t last five minutes without something!

Quinn, you never cease to impress me with your “howcum” attitude. Most folks I know wouldn’t have given the failure a second thought as they chucked the magnifier into the nearest trash can and groused about cheap Chinese crap. You, instead, not only take the thing apart to fix it (which is what I would do—I’m cheap like that) but also to analyze the failure (which I probably wouldn’t do—I’d assume that I had gotten what I paid for). You’re a girl right after my own heart.

Incidentally, not everything that comes from China is cheap crap. Some of it is expensive crap and in a few cases, actually quality merchandise. However, I do get a little nervous when I see “Made in China” on a hard drive. Those things aren’t lighted magnifiers…

I try to resist the “Chinese stuff is crap” meme here on Blondihacks, because I don’t fault the countries that make this stuff (and it’s not always China). They make it that way because we will buy it that way. People complain about stuff being crappy, but then usually make no effort to buy something better next time. I’m guilty of this myself- it’s so easy to sort by price on Amazon and One Click Buy the top thing on the list without much thought.

I do think, long term, this is a self-correcting problem. People will eventually get tired of buying and throwing away junk. I think we’re just in the mid-stages of a globalization gold-rush at the moment, and people are still high on the buzz of getting everything so cheaply.

Either that, or this will all come to an end when oil prices go up and it ceases to be cost effective to load up city-sized container ships with plastic trinkets and steam them all over the planet to save a few cents on manufacturing.

I try to resist the “Chinese stuff is crap” meme (sic) here on Blondihacks…

Before China, it was Taiwan, and before Taiwan, it was Japan. If pressure on the Chinese to improve product quality, as well as quality-of-life for their people, succeeds, as it did in Taiwan and Japan, someone somewhere else with a large labor force that is will to work for chicken feed will take over. This pattern has existed since at least World War II.

They make it that way because we will buy it that way.

No argument there. Vidi Walmart, where it’s always the low price. As long as shoppers continue to demand low price instead of high quality, the incentive of the Chinese and others to produce junky goods for North American consumption will remain strong. The problem is that oftentimes a consumer who is willing to pay more to get more can’t, as the quality item isn’t available at any price.

I do think, long term, this is a self-correcting problem.

Most likely that is the case, although it will depend on how the economy goes. Those who cannot afford quality merchandise will continue to buy the “cheap crap” no matter what.

…will all come to an end when oil prices go up and it ceases to be cost effective to load up city-sized container ships with plastic trinkets…

I’ve often contemplated the economics of operating a 100,000 ton ship to schlepp goods from half way around the world to North America, not to mention the costs associated with trans-shipment when the ship reaches our shores. So I too think that is only a matter of time before the transportation costs generated by petroleum consumption rise to an uneconomical level. Of course, I wouldn’t be surprised to learn that someone has funded the construction of a fleet of nuclear-powered cargo ships to eliminate oil from the equation… 🙁

Incidentally, this is what I use for close-up work. http://www.mcmaster.com/#1500t1/=rvnxy8

“Of course, I wouldn’t be surprised to learn that someone has funded the construction of a fleet of nuclear-powered cargo ships to eliminate oil from the equation… ”

Or maybe when the oil is gone, or gets too expensive we will return to the days of the clipper sailing ships powered by large sheets of linen.