Rescuing my cardio machine from the scrap heap once again.

As I’ve often said on this blog, so many consumer products seem to have one component in them that halves the life of the entire system. In this case, it’s my elliptical cardio machine. This is the same machine that I converted to mains power a while back.

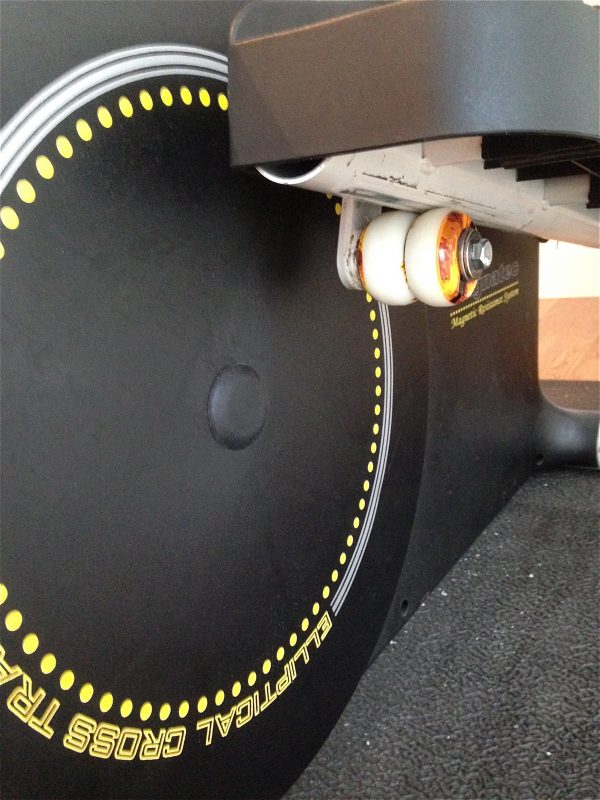

The crux of the machine is that the foot pedals, which are mounted on steel pipes, ride back and forth on top of two crank arms. These crank arms spin the magnetic resistance unit. Rather than being rigidly attached to the cranks, the foot pedal pipes ride on U-groove rollers. I don’t know for sure why it’s designed this way, but these U-groove rollers are the Achilles’ Heel of this machine. They seem to last about 6 years. I know this because the machine is 12 years old, and I’ve replaced them once already. Last week, they failed again.

The problem is, these rollers are 100% pure weapons-grade unobtainium. I bought the machine inexpensively, because it was a discontinued model at the time. So six years ago, when the rollers failed the first time, spare parts were already nearly impossible to get for it. After a great deal of googling, a lot of phone calls, and a lot of emails, I managed to find an exercise machine dealer in Australia who used to sell this machine and happened to have a pair of these rollers on his shelf. He was reluctant to ship them all the way to the United States, but I talked him into it, and it was a big score. That kept the machine going until now. This time around, I knew I had no hope of getting these rollers through conventional channels.

The rollers are a tricky beast that I haven’t seen anywhere else. They are a basic U-groove profile, except they have a boss at one end, and a recess at the other. They are also a composite of some kind of hard plastic (the black portions) and some kind of nylon or polyethelene. I figured I didn’t need to match them exactly. Any kind of nylon (or similar) U-groove roller of the right overall dimensions could be made to work.

I started by trying to source them from the usual suspects. I tried McMaster Carr, Grainger, Amazon Supply, eBay, and a dozen specialty companies like American Roller. No luck, and I learned way more about nylon and polyethylene roller products than I ever wanted to know. I spent hours staring at page after page of rollers, looking for something that would work. I even scoured the Chinese factory-direct marketplaces, like alibaba. I found a lot rollers that were the right profile, but much too small. These are 46mm in diameter, 40mm wide, and a 20mm bore. That turns out to be quite large by the standard of U-groove rollers.

After a while, I had to concede that these rollers could no longer be bought. It was time to get creative.

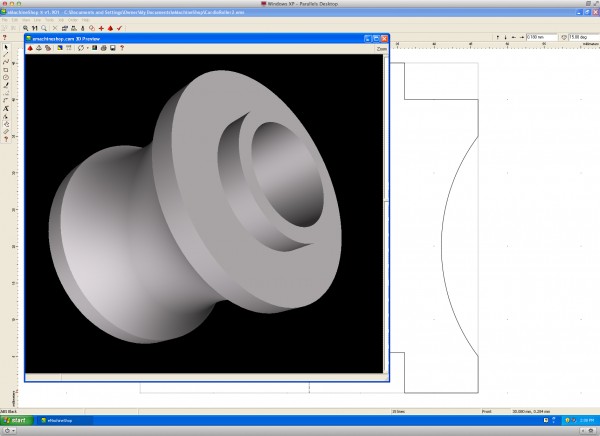

My next idea was eMachineShop. They are a company that will make any part you want, in a whole range of materials. It may be 3D printed, or it may be milled from stock, depending on the shape, strength requirements, and material needed. You download and install their special lightweight CAD software, model your part, and place the order right there in the application. It’s quite cool, honestly. I busted out my digital calipers, and reproduced these rollers in a very durable nylon in about an hour.

The catch? The quote on these two rollers was about $200. Ouch. It seems like a great service, and I’m sure their work is worth that price, but it’s more money than I wanted to throw at this problem. The entire exercise machine is not likely worth that much anymore. I’m keeping this option in my back pocket, and may still give it a try if all else fails. If I knew for sure the nylon I chose would work for the cardio machine, I’d buy it, but it’s a $200 gamble otherwise. For liability reasons, eMachineShop will not give advice on material choice, so you do need to know something about this stuff to make sure you get the right part on the first try. There are a dozen different kinds of nylon, PVC, and polyethylene. Hell if I know which would be the best one for this application.

So back to square one. When I get stumped like this, sometimes I just sit and stare at the junk pile and hope for inspiration. Lo and behold, it struck.

Rollerblade wheels are made of a similar material, are obviously designed to carry the weight of a person under hard use, and amazingly, the center bore (minus the bearings) was very close to the large 20mm bore I needed. Two of these wheels side-by-side are close in width to the rollers, and the two wheels form a V-groove that should carry the foot-pedal pipe almost as well as the U-groove. The outer diameter is obviously much larger, but that may not matter. I decided to give them a whirl.

So, the first step was to get those bearings out. There’s a special tool for pressing them out, but I couldn’t find mine. I improvised a bearing press with a couple of sockets and a C-clamp.

The original rollers have a two-part metal bushing that sits inside them and rides on the crank arm. If I can get these bushings into the rollerblade wheels, they should work the same way. With the bearings removed, the bushings were a little too big. I reamed out the holes in the wheels a little bit with the Dremel, and was able to press in the bushings.

Note that none of this has to be particularly precise, because rollerblade wheels are designed to wear. If anything is a bit crooked or misaligned, the wheels will wear into shape rather quickly. Also, roller blade wheels tend to wear more on one side, which is why you’re supposed to flip them periodically. The ones I had were overdue for that. That was a bonus, because I could arrange them so the wear pattern formed a better groove for the pipe to ride in.

The machine ran really smoothly now! So, pretty pleased with myself, I proceeded to do my normal 30 minute cardio session on the spiffy reconditioned machine. Towards the end of the session, however, something started to feel… odd.

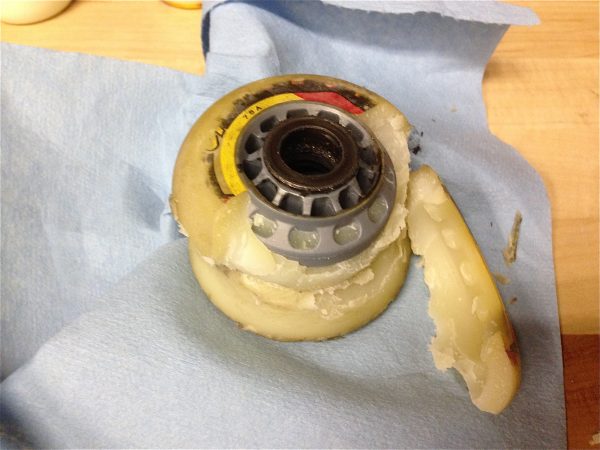

I was genuinely surprised by the magnitude and suddenness of this failure. I really thought standard rollerblade wheels wouldn’t balk a bit at having a steel pipe roll back on forth on them. These failed so dramatically, they actually coated the pipe with their own… goo.

The wheels I used are 76mm wheels with a hardness of 78A. That’s a very typical skating-along-the-beach sort of wheel. A little faster than the 72mm wheels that come with the skates, and forgiving enough for a little sand and gravel. It’s not clear if they overheated here, or they just couldn’t handle the stress being applied in this particular way. However, I was undeterred. I really felt this idea had merit, so perhaps it could be tweaked. Rollerblade wheels come in all sort of sizes and materials, so perhaps another one would work better.

I decided to go to the opposite extreme (no pun intended). There’s a particular sub-genre of rollerblading called Aggressive. The wheels in this category are designed for rail sliding, stair bashing, grinding, etc. They are generally smaller, more slippery, and much harder. These are also known as grind wheels or anti-rocker wheels. A quick look online turned up these festively-decorated fellows.

These new wheels are 101A hardness, which is much much harder than the others. As an added bonus, the outer diameter is 47mm, which is nearly exactly what the original exercise machine rollers where. They were on sale for $26 shipped. Score! If I can get another six years out of this machine for $26, that’s a major victory. So, can these new wheels take the punishment?

The longer I can put off replacing this thing, the more awesome the world is. Given the choice, I’ll take “repair” over “replace” every time. I’ve already doubled the life of this thing once- can I do it again? Check back in six years and find out.

The bearings of the DIY world seem to be mounted in skating wheels…

Love it!

Q,

Dang. Talk about catastrophic failure! I’d have thought those wheels were industructable. Are you related to the Flash 😉

Quote:

The longer I can put off replacing this thing, the more awesome the world is. Given the choice, I’ll take “repair” over “replace” every time.

I love that way of thinking. 🙂 My girlfriend rolled her eyes at me the second time I repaired the enamel paint on the microwave, where the frame had arced to the door through some butter or something, and burned through the enamel. It’s still going strong though.

Please report to the nearest Re-Education Office to cleanse your mind of those anti-consumerist thoughts. CONSUME! THROW AWAY! GOTO 10!

I have an idea as to the failure of the used wheels: used in their usual design (for skates) they would tend to roll in the same direction repeatedly for most of their lives, maybe being flipped occasionally to even wear, as you pointed out. in the cardio machine application, they are being used in a reciprocating manner. perhaps the combination of the back and forth motion, along with the fact that there is no rest period (i.e. you’re never “lifting the skate”) led to their quick demise. I’ve seen a similar thing happen with used car tires coming de-laminated.

I do love and applaud your “repair not replace” mentality.

I try to do the same thing as often as I can.

I have to wonder if the skate material disagreed with something in the lithium grease, perhaps the solvent?

That was also my first thought when I saw the picture

Interesting thought! Honestly, there’s only a little bit of grease applied, and only on the metal-to-metal surfaces. I don’t believe any grease could get on the wheels, but it’s certainly a possibility.

My leading theory on the failure is a combination of heat and age. The wheels do get fairly warm during operation, and these used wheels were about 10 years old. I don’t know if rollerblade wheels have a shelf life, but I wouldn’t be surprised if they did.